Description

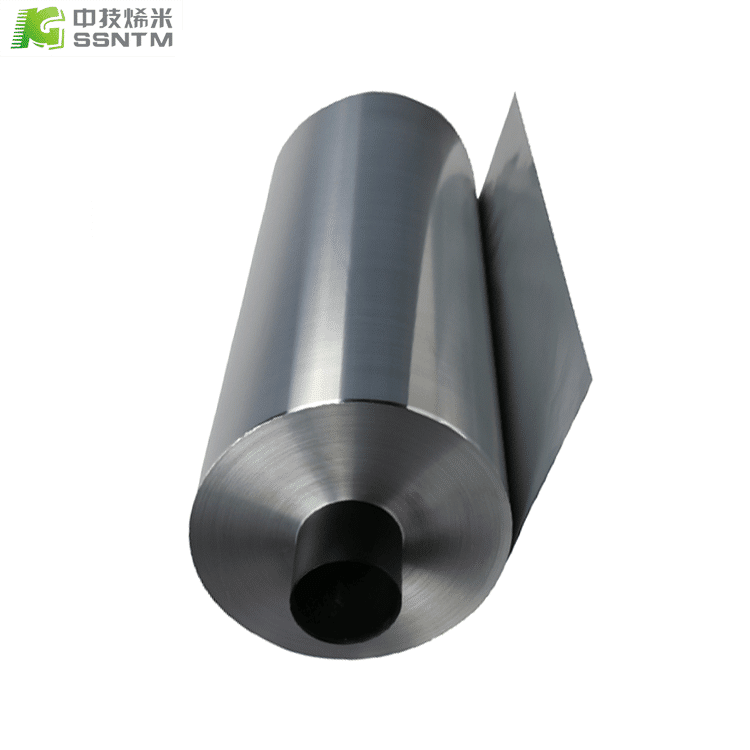

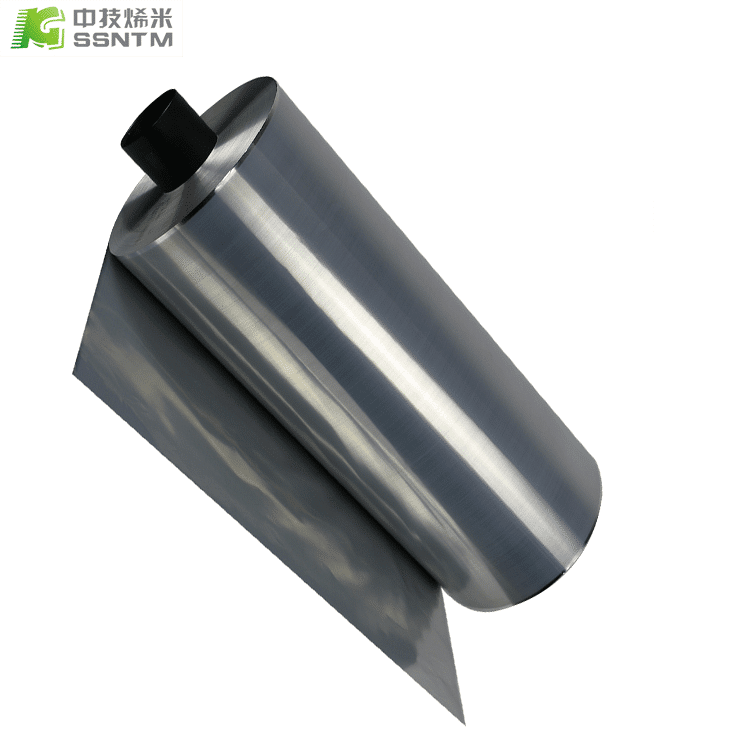

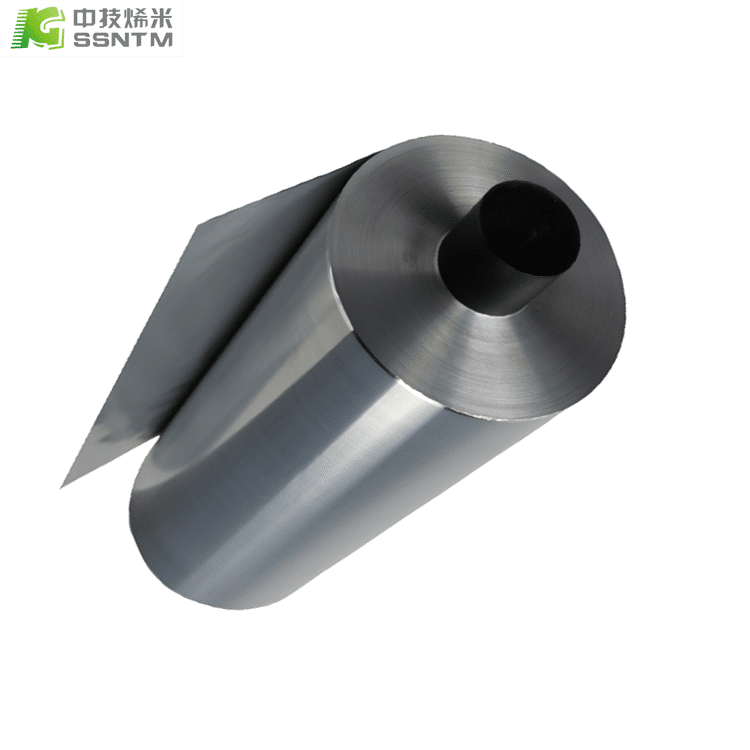

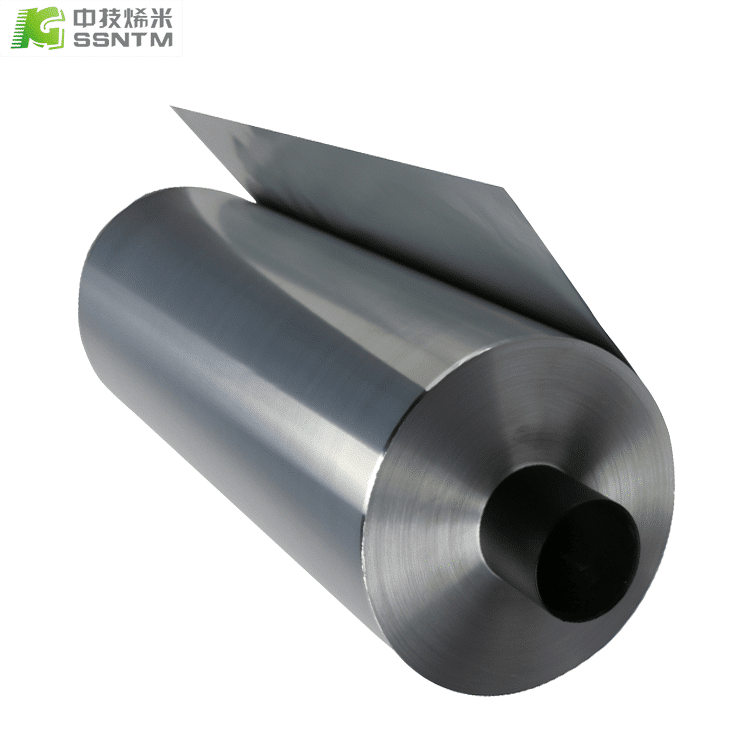

Product attributes:

Color: black, gray

Base material: aluminum foil, copper foil

Base material thickness: 10-20 μ m

Coating method: single coating, double coating

Effective coating width: customized

Material width: customized

Inner diameter of pipe core: 76mm

Packaging: wooden box

Origin: Foshan

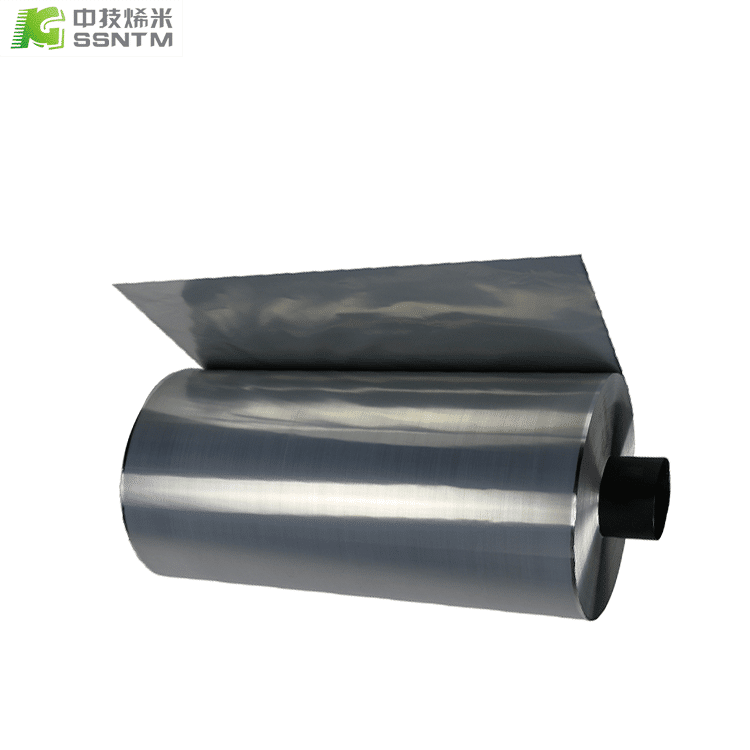

For Etched Aluminum Foil Collector Supercapacitors can be uniformly coated on the surface of aluminum foil current collector by using gravure coating technology. The thickness of coating layer can be adjusted by gravure roller mesh and coating speed.

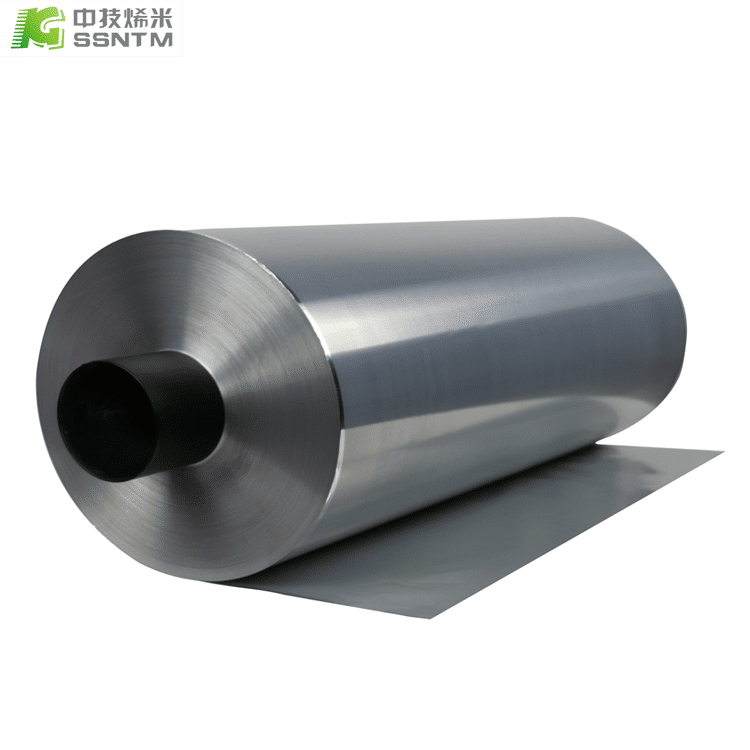

Generation of a small amount of precipitation after long term storage is allowed. Please stir till homogeneously dispersed before use.

It should be used immediately after opening Once opened. it should be stored in sealed containers and used within one month

The suggested coating thickness (double sides) is<1um (double sides areal density of 0.08-0.1 g/cm2) . We can manufacture the graphene coated foil according to customer’s requirement.