Lithium metal batteries (LMBs) are highly favored due to their much higher energy density than graphite anode lithium batteries. However, lithium metal batteries have problems with lithium dendrites and unstable solid electrolyte interfaces. Therefore, improving the cycling performance and overall safety of lithium metal batteries has become an important research direction. Cu CCs, represented by Cu, have a significant impact on the nucleation/growth, local current density, and Li+flux distribution of lithium. However, the commonly used planar Cu CCs do not have ideal performance in batteries. In view of this, numerous studies have improved Cu CCs with the aim of reducing local current density, inhibiting lithium dendrite growth, and improving the Coulombic efficiency of the battery. Recently, researchers such as BaizengFang, David P. Wilkinson, and Zhou from the University of British Columbia have systematically summarized modification strategies for Cu CCs, providing guidance for the rational design of Cu CCs with specific structures and properties. A critical discussion was conducted on common errors in data description and analysis in literature in this field, and insights were provided on key challenges and future directions in this research direction.

The use of lithium metal as an electrode material in rechargeable batteries has attracted significant attention due to its high theoretical capacity and low electrode potential. However, the deposition and growth of lithium metal during battery cycling can lead to issues such as dendrite formation, low Coulombic efficiency, and safety concerns.

To address these challenges, researchers have focused on modifying the copper (Cu) current collector, which is commonly used in lithium metal batteries. Here is an overview of the research progress on modified Cu collectors in lithium metal batteries:

1. Surface Coating: Several studies have investigated surface coatings on the Cu current collector to improve the stability and compatibility with lithium metal. Coatings such as carbon-based materials, polymer films, and ceramic layers have been explored to prevent direct contact between lithium and Cu, reducing the formation of lithium dendrites.

2. Conductive Polymer Coatings: Conductive polymers, such as polypyrrole (PPy), polyaniline (PANI), and poly(3,4-ethylenedioxythiophene) (PEDOT), have shown promise as coatings on Cu collectors. These polymers can form a protective layer that enhances lithium ion transport while inhibiting dendrite growth and improving the overall performance of lithium metal batteries.

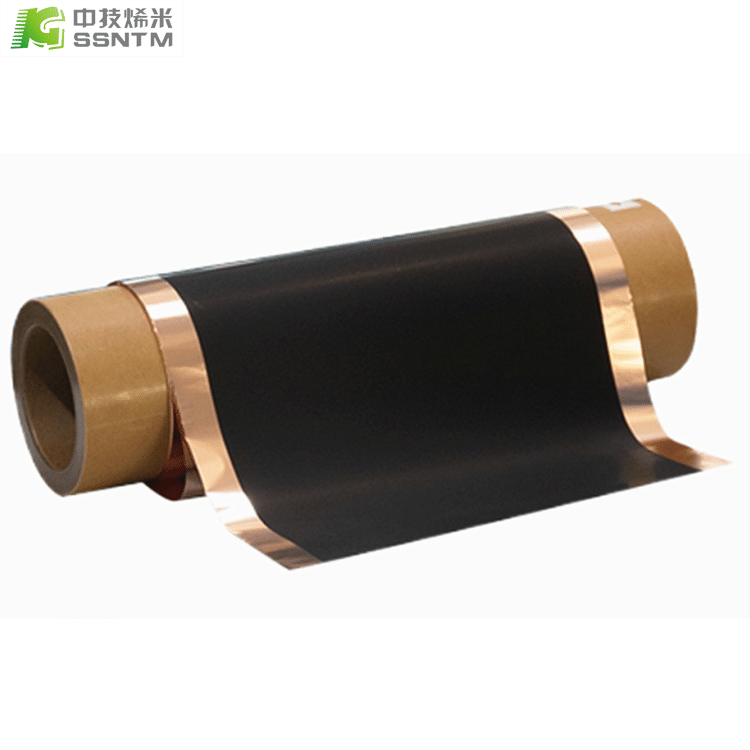

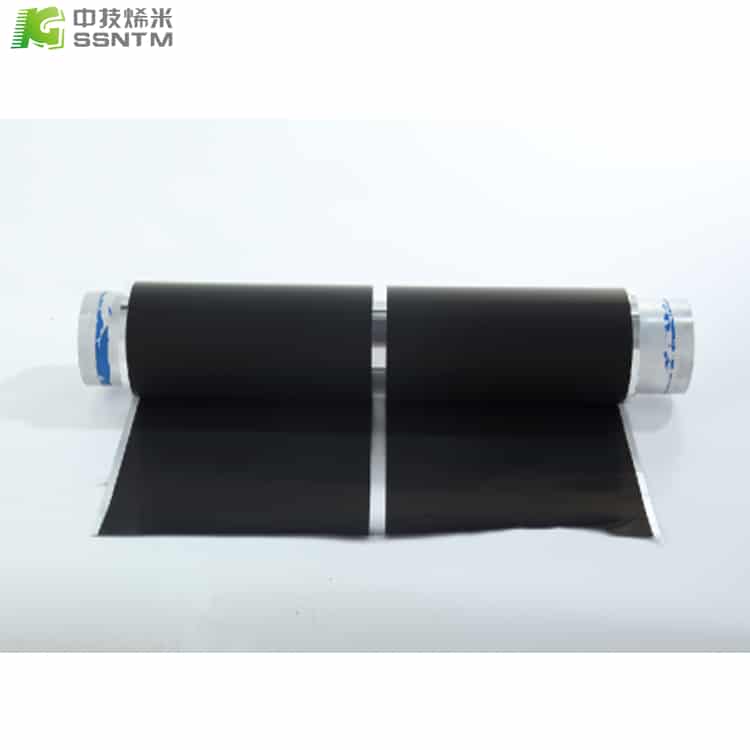

3. Nanostructured Cu Collectors: Nanostructured Cu collectors with engineered morphologies and surface properties have been investigated to mitigate the issues associated with lithium dendrite formation. Examples include nanostructured Cu foams, Cu nanowires, and Cu-coated substrates with hierarchical structures. These nanostructures provide improved surface area, reduced current density, and enhanced lithium plating/stripping behavior.

4. Alloyed Cu Collectors: Another approach involves incorporating alloying elements into the Cu collector, such as nickel (Ni), cobalt (Co), or silver (Ag). These alloyed Cu collectors can alter the surface properties and enhance the mechanical strength, electrical conductivity, and lithium ion transport properties, thereby improving the performance and safety of lithium metal batteries.

5. Interfacial Protection Layers: Interfacial protection layers, such as solid electrolyte interphase (SEI) films or artificial solid-state electrolytes, can be deposited on the Cu collector surface to enhance the stability of the electrode-electrolyte interface. These protective layers contribute to suppressing dendrite formation, reducing side reactions, and improving the overall electrochemical performance of lithium metal batteries.

6. Surface Modification with Additives: Surface modification of the Cu collector with additives, such as nanoparticles or chemical modifiers, has been explored to suppress dendrite growth and improve the stability of lithium plating/stripping processes. Examples include the use of graphene, carbon nanotubes, MXenes, and surface-active agents.

7. Advanced Characterization Techniques: Researchers have employed various advanced characterization techniques, including scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and electrochemical impedance spectroscopy (EIS), to study the morphology, composition, and electrochemical behavior of modified Cu collectors in lithium metal batteries.

These research efforts aim to overcome the challenges associated with lithium metal anodes in rechargeable batteries by optimizing the Cu current collector’s properties and surface/interface interactions. By enhancing the stability and performance of the Cu collector, it is possible to achieve safer and more efficient lithium metal batteries, thereby promoting the development of next-generation energy storage technologies.