Research and Progress on Current Collecting Modification for Lithium Metal Negative Electrodes

Lithium metal has an ultra-high theoretical specific capacity density (3680 mA · h/g) and a low Reduction potential (-3.04 V, relative to the Standard hydrogen electrode), which is considered as the “Holy Grail” of negative electrode materials for high energy density batteries. However, a series of problems such as low Coulomb efficiency, short cycle life, and internal short circuit caused by the growth of lithium dendrites and high reactivity to electrolytes seriously restrict the practical progress of metal lithium negative electrodes. In practical electrochemical systems, the collector serves as the substrate for the deposition/removal of metallic lithium, and its surface properties play a crucial role in the cyclic stability of lithium negative electrodes. This article systematically summarizes various interface modification strategies for stable metal lithium anodes from two aspects: the surface composition of the negative electrode current collector and the design of microstructure, including the construction of lithium-friendly surfaces, the modification of nanoscale electron/ion mixed conductive networks, and the design of surface microstructure. Targeted modifications to the interface and structure of the collector can effectively regulate the electrodeposition of metallic lithium and promote the practical application of metallic lithium negative electrodes in high energy density battery systems.

The development of high-performance lithium metal batteries relies on addressing the challenges associated with the lithium metal negative electrode, such as dendrite formation, low Coulombic efficiency, and limited cycle life. Researchers have been actively investigating various current collecting modifications for lithium metal negative electrodes to mitigate these issues. Here is an overview of the research progress in this area:

1. Surface Coating: Surface coating techniques involve depositing a protective layer on the lithium metal surface to inhibit direct contact between lithium and the electrolyte, thereby reducing dendrite growth. Coatings like solid electrolyte interphase (SEI) films, polymer coatings, and ceramic coatings have been explored to enhance the stability and cycling performance of lithium metal electrodes.

2. Interlayer Integration: Interlayers placed between the lithium metal electrode and the current collector can act as a physical barrier to suppress dendrite growth and improve the stability of the electrode-electrolyte interface. Materials used for interlayers include polymers, ceramics, and solid-state electrolytes. These interlayers can provide mechanical flexibility, enhanced interface stability, and effective ion transport.

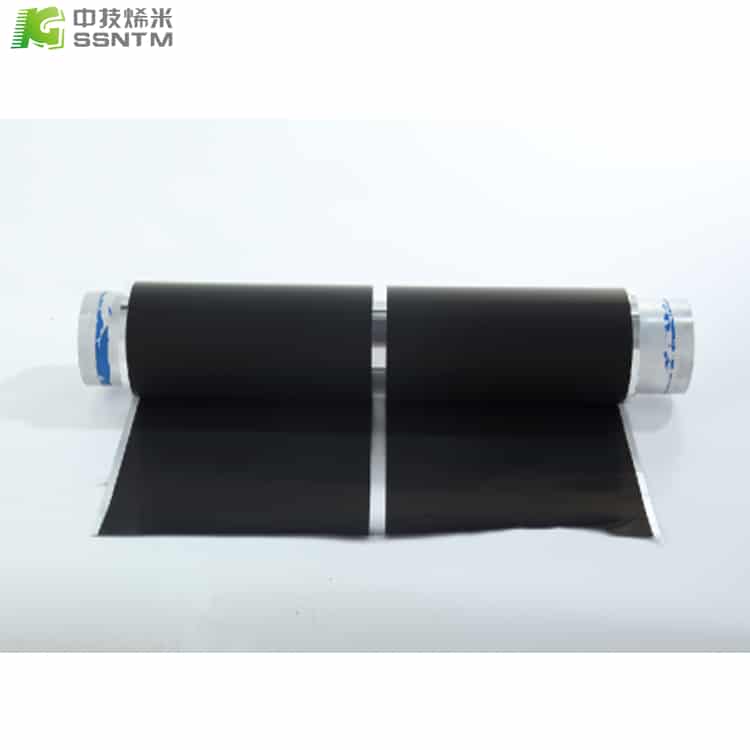

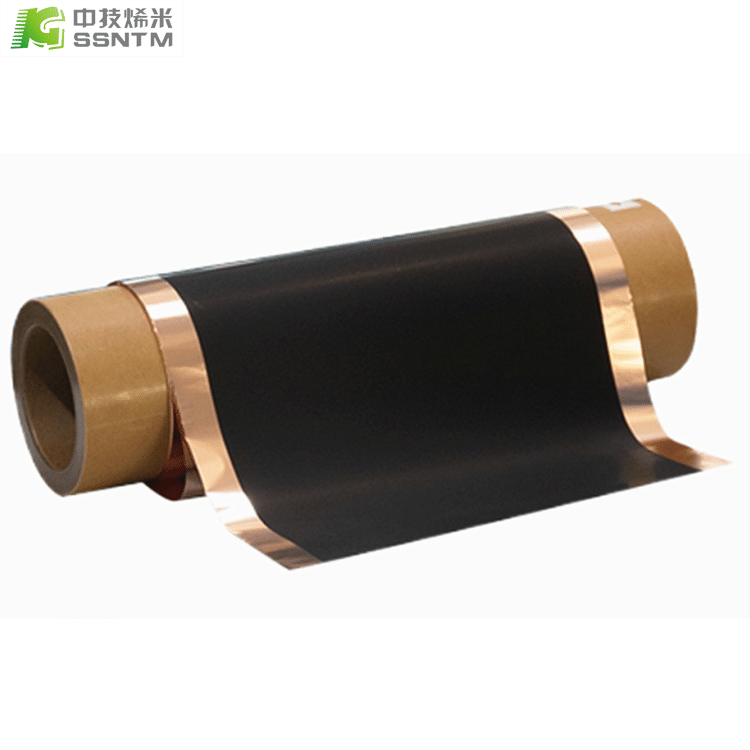

3. Alloying Current Collectors: Modifying the current collector itself by incorporating alloying elements offers a promising approach to improve the performance of lithium metal negative electrodes. Alloying with metals like copper (Cu), nickel (Ni), or silver (Ag) can alter the properties of the current collector, enhancing its mechanical strength, electrical conductivity, and resistance to dendrite formation.

4. Conductive Polymer Coatings: Applying conductive polymer coatings onto the current collector can improve the electrochemical performance of lithium metal electrodes. Polymers such as polypyrrole (PPy), polyaniline (PANI), and poly(3,4-ethylenedioxythiophene) (PEDOT) can form thin and conformal coatings that promote uniform lithium deposition and inhibit dendrite growth.

5. Nanostructured Current Collectors: The use of nanostructured current collectors has gained attention due to their enhanced surface area and unique properties. Nanostructured materials like carbon nanotubes, graphene, and metal oxides can be employed as current collectors or as coating materials to improve the stability and electrochemical performance of lithium metal electrodes.

6. Surface Modification with Additives: Another approach involves modifying the lithium metal electrode surface with additives to suppress dendrite growth and enhance electrochemical performance. Additives such as electrolyte additives, nanoparticles, and chemical modifiers can be incorporated to modify the surface/interface properties and regulate the lithium deposition behavior.

7. Advanced Characterization Techniques: Researchers employ advanced characterization techniques, including scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and electrochemical analysis, to study the morphology, composition, and electrochemical behavior of modified current collectors for lithium metal negative electrodes.

These research efforts aim to enable the practical utilization of lithium metal as a high-capacity negative electrode, contributing to the development of next-generation rechargeable batteries with improved energy density, safety, and cycling stability. The progress in current collecting modification brings us closer to realizing the full potential of lithium metal batteries in various applications, including portable electronics and electric vehicles.